Many medical device companies choose to work with either silicone or thermoplastic, but Rose offers a competitive advantage because we do both. This specifically applies to wire reinforcement in cannula bodies. The cannula tube assembly and manufacturing techniques used to accomplish wire reinforcement in thermoplastics and silicones are very different, but Rose has experience developing both types into full-scale production.

Wire Reinforced Cannula

Silicone Wire Reinforcement

Silicone is often considered a premier material in cannula tub assembly and medical device manufacturing because of the softness and flexibility. The beauty of wire reinforcement is you retain those advantages while also achieving crush, kink, and torque resistance.

Silicone is often considered a premier material in cannula tub assembly and medical device manufacturing because of the softness and flexibility. The beauty of wire reinforcement is you retain those advantages while also achieving crush, kink, and torque resistance.

Rose has manufacturing space designed to manufacture silicones by closely controlling the environment in the room year-round. In this space, we use custom automated equipment to aid our proprietary process and provide our customer with exceptional results in cannula tub assembly. An abbreviated list of our capabilities includes:

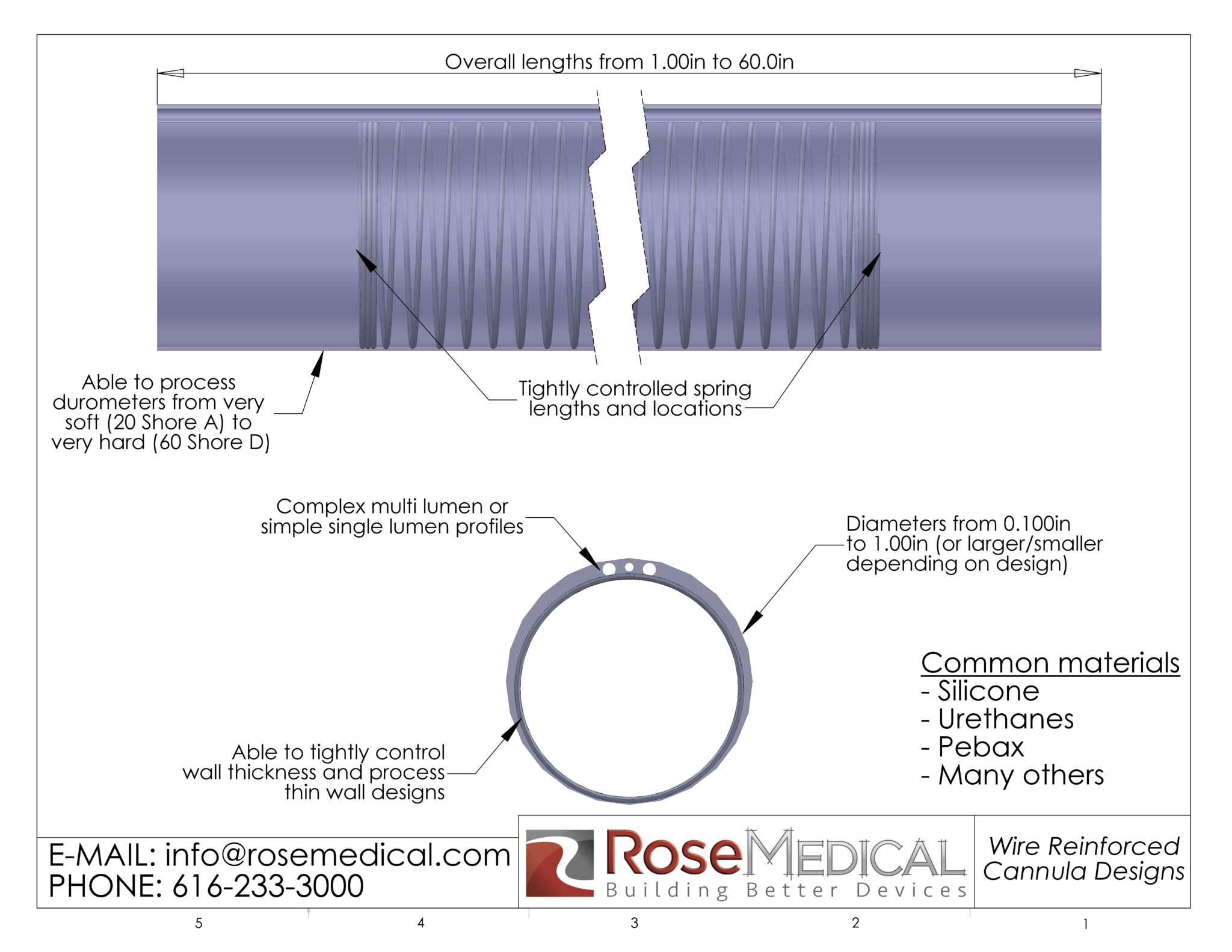

- Inner diameters from 0.050” – 1.0”

- Reinforced lengths up to 48”

- Wall sections as thin as 0.010”

- Multiple reinforced sections

- Single lumen and multi-lumen tubes

Once reinforced, we can use our silicone molding and device assembling capabilities to take your device to the next step.

Thermoplastic Wire Reinforcement

While co-extrusion is an efficient process for continuous spools, a different approach is required when laminating thermoplastic materials in discrete lengths. Rose uses our own custom design machines to assemble and laminate cannula that require wire-reinforcement between layers of thermoplastic materials. This cannula tub assembly process allows us to tailor the reinforcement to the desired design.

- Braid or coil reinforcement

- Starting and stopping reinforcement as needed

- Embedding marker bands or stiffening/supporting materials into the cannula bodies

- Using etched PTFE liners for lubricity on the inner diameter

After the cannula tube is assembled and manufactured, we can use catheter tip forming or pad printing and laser marking to further process the device.